Introduction to EGRS

Breakthrough in Gold Refining Technology

The purpose of this introduction is to inform the gold refining industry of the Enviro Gold Refining System’s breakthrough in gold refining technology. The EGRS system is already patent pending. You will find a valuable summary of the dramatic benefits to the $300 billion gold refining industry along with some details on EGRS.

Benefits

- Totally green and environmentally friendly

- Produces no hydroxides or toxic fumes

- 99.99% gold sponge finest from refining

- 99.99% recovered AU, AG, PT, PD, CU, ZN

- 99.99% precious metals recovery and accountability

- 10X faster cycle rate/Less required labor/90% less chemical usage

- Totally automated & modular system

- Estimated cost savings from operations for a large refinery is between $60,000-$70,000 per day$

- Additional daily Income from precious metals recovery is approximately $100,000+

- Patent Pending technology that replaces 150-year-old processes

- Less hazardous to workers

- Refinery requires a smaller footprint

- Replaces hydroxides with saleable products

- EGRS chemistry uses metal tanks, piping, etc. versus breakable Pyrex

Mr. David Caldwell, Inventor

EGRS is the result of many years of combined research and industry experience of its team leader. Mr. David Caldwell is an inventor and former gold refinery owner for more than 30 years. Researchers assisting Mr. Caldwell include Ph.D. level chemists and various respected industry and business consultants. Mr. Caldwell’s personal knowledge coupled with that of his experts has resulted in EGRS combining modern-day chemistry, equipment, computerized automation, and practical gold refining to achieve dramatic results and many millions of dollars in savings per year. Additionally, precious metals recoveries are increased, and base metal toxic wastes are replaced by saleable base metal products.

The EGRS Technology Has Been Proven to Be Ready for Commercial Use

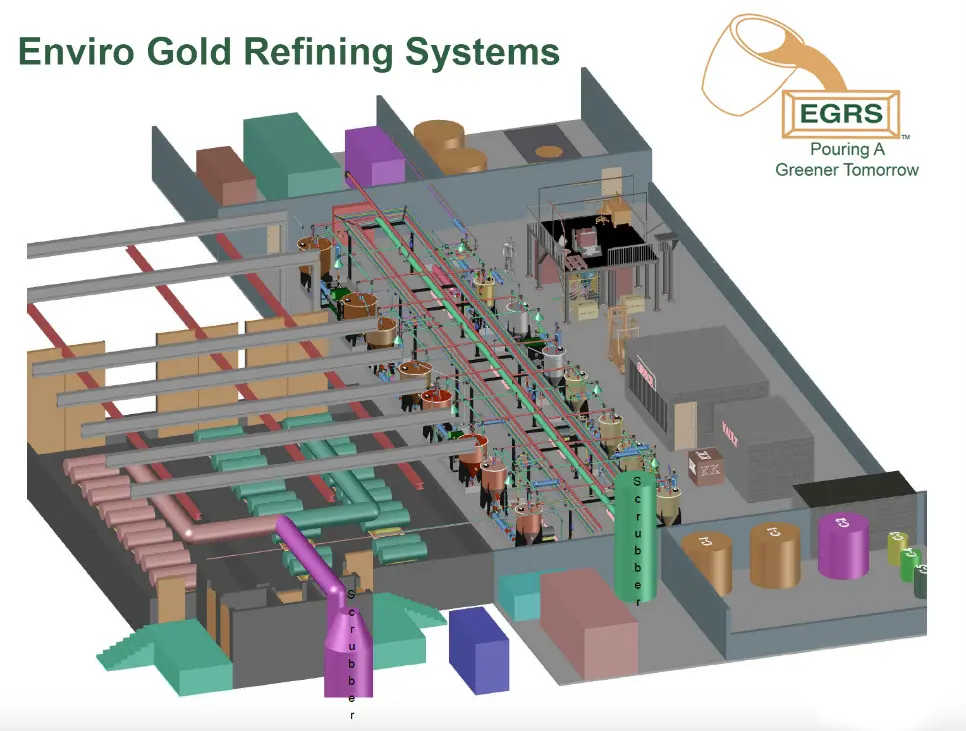

In March 2020, EGRS technology was successfully demonstrated at an independent testing lab. EGRS then assembled their own testing lab in Tampa, Florida in May 2020 to continue testing and perform demonstrations for gold refiners worldwide. The EGRS team has developed seven different size units to meet the varying needs of refining industries. 3D AutoCAD has been used for design work. We have completed extensive research on expenses of the new EGRS system and compared them with expenses of the Aqua Regia system.

General Contractor (GC) Selected

We have more than two dozen engineers in the United States, 60 in France, and 20 in India. Our GC has been working with EGRS over the past two years to ensure quality of design. Our GC specializes in new industrial systems and has decades of experience building chemical equipment (including modular) for clients throughout the world including Dow Chemical. The GC handles final engineering, building, installing, training, and maintaining of the new system. Mr. Caldwell, working with input from the GC, has already created 3D AutoCAD detailed scalable plans for a larger and smaller refining plant. We have sourced vendors for each item required.